The guide provides information on installing PVC electrical conduit, including cutting and bending, to ensure a safe and proper installation, using handsaws or cutters, and heat bending conduit to required shapes easily online.

Overview of PVC Conduit Installation

The process of installing PVC conduit involves several key steps, including planning, measurement, and execution.

A thorough understanding of the installation process is crucial to ensure a successful and safe installation.

The guide provides a comprehensive overview of the installation process, including the materials and tools required.

It also covers the different methods of cutting and bending PVC conduit, such as using handsaws or cutters, and heat bending conduit to required shapes.

Additionally, the guide discusses the importance of proper sizing and fitting of the conduit to ensure a secure and reliable connection.

By following the guidelines outlined in the installation guide, individuals can ensure a safe and proper installation of PVC electrical conduit.

The guide is an essential resource for anyone involved in the installation of PVC conduit, including electricians, contractors, and DIY enthusiasts.

It provides a detailed and easy-to-follow approach to installing PVC conduit, making it an invaluable tool for anyone looking to complete a successful installation.

The guide is available online, making it easily accessible to anyone who needs it.

Compliance with Electrical Codes and Regulations

Importance of Following Industry Standards

Following industry standards is crucial for ensuring the safe and proper installation of PVC electrical conduit. The use of industry standards provides a framework for installers to follow, helping to prevent errors and ensure that the installation meets the required safety and performance criteria. By following these standards, installers can help to prevent electrical shocks, fires, and other hazards. The industry standards also provide guidelines for the selection and use of materials, including PVC electrical conduit, to ensure that they are suitable for the intended application. Additionally, following industry standards can help to ensure that the installation is compliant with relevant regulations and codes, reducing the risk of legal and financial penalties. Overall, following industry standards is essential for ensuring the safe and reliable installation of PVC electrical conduit, and for protecting people and property from electrical hazards. Using online resources and guides can also help installers to stay up-to-date with the latest industry standards and best practices.

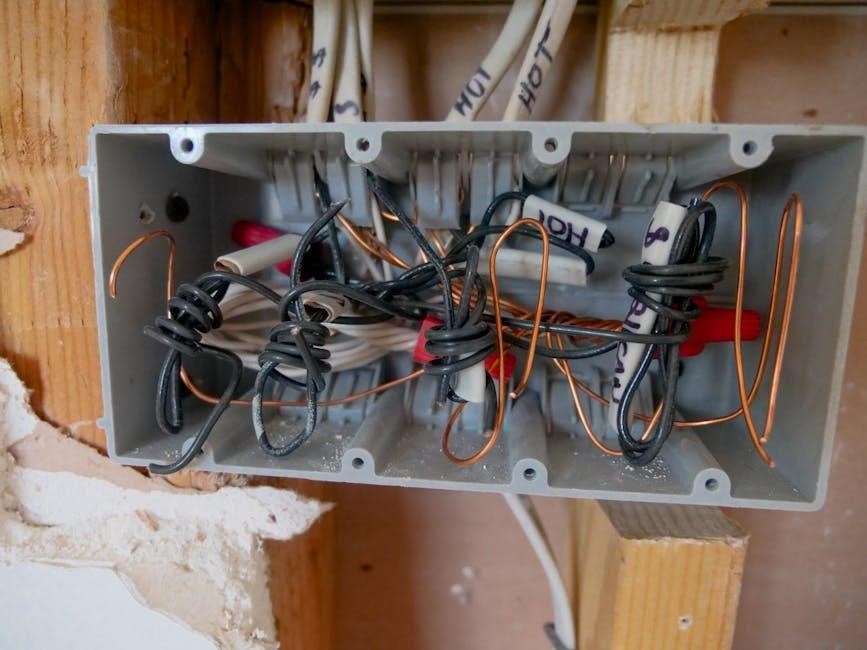

Tools and Equipment Required for Installation

Handsaws, cutters, and heat bending equipment are necessary for installing PVC electrical conduit, ensuring a proper and safe installation, using specific tools and equipment, easily found online, every time.

Cutting and Bending Tools for PVC Conduit

To cut PVC conduit, various tools can be used, including handsaws, fine-toothed saws, and conduit cutters, which are designed to make clean cuts without damaging the conduit.

For bending PVC conduit, heat bending equipment is necessary, which allows for precise control over the bending process, ensuring that the conduit is bent to the required shape without kinking or damaging the conduit.

It is essential to use the correct tools and equipment for cutting and bending PVC conduit to ensure a safe and proper installation, and to prevent damage to the conduit or injury to the installer.

The use of proper cutting and bending tools also helps to ensure that the conduit is installed in accordance with industry standards and regulations, which is critical for ensuring the safety and reliability of electrical systems.

By using the correct tools and equipment, installers can ensure that PVC conduit is cut and bent accurately and efficiently, which helps to reduce installation time and costs.

Step-by-Step Installation Process

Installers follow a sequence of tasks, including planning, measuring, and assembling conduit systems using various techniques and tools easily online every day.

Preparing the Conduit for Installation

To prepare the conduit for installation, it is essential to inspect the conduit and fittings for any damage or defects. The conduit should be cut to the required length using a hacksaw or a conduit cutter. The cut ends of the conduit should be deburred to prevent any sharp edges from causing damage to the wires or cables. The conduit should also be cleaned to remove any dirt or debris that may interfere with the installation process. Additionally, the fittings and connectors should be prepared by applying a lubricant to the threads to ensure a smooth and secure connection. By following these steps, the conduit can be properly prepared for installation, ensuring a safe and reliable electrical system. The preparation process is crucial to ensure that the conduit is installed correctly and functions as intended. Proper preparation can help prevent errors and ensure a successful installation.

Troubleshooting Common Installation Issues

Identify and resolve issues with conduit installation using diagnostic techniques and tools to ensure safe and proper functioning of electrical systems online easily every time with correct methods.

Addressing Discrepancies in Installation Specifications

To ensure compliance with industry standards, it is essential to address any discrepancies in installation specifications. This can be achieved by carefully reviewing the installation guide and comparing it with the actual installation. Any discrepancies found should be reported to the relevant authorities, such as the manufacturer or the regulatory body. The installation guide should provide clear instructions on how to address discrepancies, including procedures for correcting errors and notifying the relevant parties. By following these procedures, installers can ensure that the installation meets the required standards and is safe for use. The guide may also provide information on how to document discrepancies and corrections, which is essential for maintaining records and ensuring accountability. Additionally, the guide may include troubleshooting tips and techniques for resolving common issues that may arise during installation. By addressing discrepancies in installation specifications, installers can ensure a safe and successful installation.

and Final Checklist for PVC Conduit Installation

The installation of PVC electrical conduit requires careful planning and execution to ensure a safe and successful outcome. A final checklist can help installers verify that all necessary steps have been taken, including cutting, bending, and solvent welding the conduit. The checklist should also include items such as inspecting the conduit for damage, testing the electrical system, and ensuring that all connections are secure. By following the installation guide and using the final checklist, installers can ensure that the PVC conduit installation meets industry standards and is safe for use. The checklist can also serve as a record of the installation, providing a paper trail in case of any future issues or disputes. Overall, a well-planned and executed PVC conduit installation is essential for ensuring the safe and reliable operation of electrical systems. Proper installation can help prevent accidents and ensure compliance with regulatory requirements.